Custom Foam Inserts: The Backbone of Safe Equipment Shipping

Custom Foam Inserts: The Backbone of Safe Equipment Shipping

When shipping valuable equipment, the difference between safe arrival and costly damage often comes down to what’s inside the case. Custom foam inserts have become an essential component in the protective packaging industry, providing tailored protection that prevents equipment from shifting, absorbing impact, and ensuring your valuable items arrive exactly as they left.

When shipping valuable equipment, the difference between safe arrival and costly damage often comes down to what’s inside the case. Custom foam inserts have become an essential component in the protective packaging industry, providing tailored protection that prevents equipment from shifting, absorbing impact, and ensuring your valuable items arrive exactly as they left.

At Vol Case & Container, we’ve seen firsthand how proper internal packaging can make or break a shipment’s success. Whether you’re transporting military equipment, medical devices, sensitive electronics, or industrial machinery, the right custom foam insert transforms a standard shipping container into a precision protective solution.

Understanding Custom Foam Inserts

Custom foam inserts are specially designed and cut foam pieces that fit precisely around your equipment inside a protective case or container. Unlike generic packaging materials, these inserts are tailored to the exact dimensions and contours of your specific items, creating a snug, secure fit that eliminates movement during transit.

Types of Protective Foam Materials

The effectiveness of foam packaging depends largely on selecting the right material for your specific application:

-

Standard Polyethylene Foam: Versatile and economical for general protection needs.

-

Crosslinked Polyethylene Foam: Offers similar protection compared to standard polyethylene foam, but with a more appealing finish.

-

Anti-Static Foam: Specifically designed for electronic components, circuit boards, and computer chips to prevent damage from static electricity.

-

High-Density Foam: Provides superior protection for heavier items.

-

Polyurethane Foam: Lightweight, soft foam with improved scratch prevention making it ideal for cameras and lenses..

The selection process involves analyzing not just the dimensions of your equipment, but also its weight, fragility, and specific vulnerabilities to impact, vibration, or environmental factors.

Benefits of Custom Foam Protection

Superior Impact Resistance

Custom foam inserts provide exceptional protection against the physical stresses of shipping and handling. The precision-cut foam creates a complete cushioning system that absorbs and distributes impact forces that would otherwise transfer directly to your equipment. When properly designed, these foam solutions are fully shock-absorbent, meaning knocks and bumps during transit won’t affect your products. This level of protection is particularly crucial for items with sensitive components or precise calibrations that could be compromised by even minor impacts.

Perfect Fit for Irregular Shapes

One of the greatest advantages of custom foam is its ability to accommodate items with non-uniform shapes. Standard packaging materials often leave gaps around irregularly shaped equipment, allowing for movement and potential damage. Custom foam, however, can be precisely cut to match even the most complex contours.

This perfect-fit approach means:

-

Equipment remains completely immobilized during transit

-

Pressure points are eliminated through even support

-

Multiple items can be organized and separated within a single case

-

Access points can be designed for easy removal and replacement

Long-Term Protection for Stored Equipment

Beyond shipping protection, custom foam inserts provide excellent long-term storage solutions. Equipment that sits in storage for extended periods can suffer damage from dust, moisture, and gradual settling. Custom foam creates a stable, protective environment that maintains your equipment’s condition over time.

Custom Foam Manufacturing Processes

The creation of precision foam inserts involves several specialized techniques, each offering different advantages depending on your equipment protection needs.

Advanced Cutting Methods

Modern foam insert manufacturing employs several cutting technologies to achieve precise results:

-

CNC Routing: Computer-controlled cutting for extremely accurate, complex designs. Best for foam sets with curved and variable depths.

-

Laser Cutting: Provides clean edges and intricate detail work.

-

Waterjet Cutting: Excellent for thicker foam materials.

-

Die-Cutting: Cost-effective for larger production runs

These advanced methods ensure that your foam inserts match your equipment’s dimensions with millimeter precision, creating the secure fit necessary for maximum protection.

Custom Design Process

Creating effective foam inserts begins with a thorough assessment of your equipment and shipping requirements. The process typically includes:

-

Detailed measurement and 3D modeling of your equipment

-

Selection of appropriate foam materials and densities

-

Design of the insert layout, including compartments and access points

-

Prototype creation and testing

-

Production and quality control

At Vol Case & Container, our design team works closely with clients to understand not just the dimensions of their equipment, but how it will be used, transported, and stored. This comprehensive approach ensures that the final foam solution addresses all protection requirements.

Choosing the Right Foam Insert Solution

Matching Foam to Application

|

Factor |

Consideration |

Example Application |

|

Weight |

Heavier items require denser foam |

Industrial machinery parts |

|

Fragility |

Delicate items need softer, more shock-absorbent foam |

Calibrated instruments |

|

Environmental Exposure |

Temperature extremes or moisture require specialized materials |

Outdoor or military equipment |

|

Frequency of Access |

Regularly accessed items benefit from durable foam |

Field service equipment |

|

Static Sensitivity |

Electronic components require anti-static properties |

Circuit boards, computer components |

Case Compatibility

Custom foam inserts can be designed to fit virtually any protective case or container, including:

-

Corrugated shipping boxes

-

Military-specification containers

The foam insert and outer container work as a system, with each component contributing to the overall protection. At Vol Case & Container, we can help you select the optimal combination based on your shipping requirements and budget constraints.

Industry Applications for Custom Foam

The versatility of custom foam inserts makes them valuable across numerous industries and applications.

Military and Defense Equipment

Military operations depend on equipment arriving in perfect working condition, often after transport through extreme environments. Custom foam inserts protect sensitive electronics, weapons systems, communications equipment, and tactical gear from the rigors of deployment. The military-grade protection provided by precision foam inserts ensures that critical equipment is ready for immediate use upon arrival, regardless of the transportation conditions encountered.

Medical and Scientific Instruments

Medical devices and scientific instruments represent some of the most sensitive and valuable equipment requiring shipping protection. Custom foam solutions protect these precision instruments from:

-

Calibration disruption due to impact

-

Contamination from environmental exposure

-

Component damage from vibration

-

Cross-contamination between items

For medical equipment manufacturers and research facilities, custom foam inserts provide the assurance that their valuable instruments will arrive ready for immediate use in critical applications.

Electronics and Technology

The technology sector relies heavily on custom foam protection for shipping everything from server components to consumer electronics. Anti-static foam options are particularly important in this sector, as they prevent damage from electrostatic discharge that can destroy sensitive electronic components.

Working with a Custom Foam Provider

What to Look for in a Foam Packaging Partner

When selecting a company to create your custom foam inserts, consider these key factors:

-

Experience: Look for providers with extensive experience in your specific industry

-

Material Options: Ensure they offer a wide range of foam types and densities

-

Cutting Technology: Advanced cutting methods provide more precise results

-

Design Capabilities: The ability to create complex, multi-layer designs

-

Production Capacity: Can they handle your order volume, from single units to thousands?

The Custom Foam Design Process

At Vol Case & Container, our approach to custom foam design focuses on creating solutions that perfectly match your protection requirements. Our process includes:

-

Consultation: We begin by understanding your equipment, shipping methods, and protection needs.

-

Material Selection: Our team recommends the optimal foam type and density.

-

Design Development: We create precise CAD designs for your approval.

-

Prototype Testing: For critical applications, we can create and test prototypes.

-

Production: Use advanced cutting technology for precision results.

-

Quality Control: Each insert is inspected to ensure it meets our exacting standards.

This comprehensive approach ensures that your equipment receives the exact protection it needs, whether you’re shipping a single valuable item or thousands of components.

The Cost-Benefit Analysis of Custom Foam

While standard packaging materials may seem more economical initially, custom foam inserts often provide significant cost savings over time. Consider these factors when evaluating the investment:

-

Damage Prevention: Reduced replacement costs for damaged equipment.

-

Insurance Savings: Lower insurance premiums due to decreased damage claims.

-

Reusability: Quality foam inserts can be used for multiple shipments.

-

Efficiency: Faster packing and unpacking times with designed inserts.

-

Customer Satisfaction: Improved experience when products arrive in perfect condition.

For high-value equipment, the cost of a custom foam insert is typically a small fraction of the potential replacement cost, making it a wise investment in protection.

Conclusion

Custom foam inserts represent the gold standard in equipment protection for shipping and storage. By providing tailored, precision-fit cushioning, these specialized packaging solutions ensure that valuable items arrive at their destination in the same condition they left. From military equipment to medical devices, electronics to industrial machinery, custom foam delivers the protection that standard packaging simply cannot match.

At Vol Case & Container, we understand that your equipment is valuable and often irreplaceable. Our custom foam insert solutions are designed to provide the highest level of protection, giving you confidence that your shipments will arrive safely, regardless of the challenges encountered during transit.

When considering your next equipment shipment, remember that what’s inside the case matters just as much as the case itself. Custom foam inserts aren’t just packaging – they’re an investment in the safe arrival of your valuable equipment.

About Vol Case

Volunteer Case & Container is the oldest custom crate and case manufacturer in the East TN area. Founded over 30 years ago, all of our protective packaging solutions are still designed and assembled at our facility in Oak Ridge, TN. We specialize in custom wood crates, ATA cases, wood or plastic containers, injection molded cases, and waterjet or CNC cut foam inserts. Our customers span a variety of industries including nuclear, government, aerospace, military, medical, R&D, and more. Our team has experience designing and building everything from huge wood crating for 70,000+ lbs machinery to small injection molded cases for key-sized objects. Whatever your needs, our team works on quick turnaround times to provide you with high quality protective packaging. Contact us today for a free quote.

Our Products

No matter the size or sensitivity of your product, Vol Case has a protective packaging shipping solution for you.

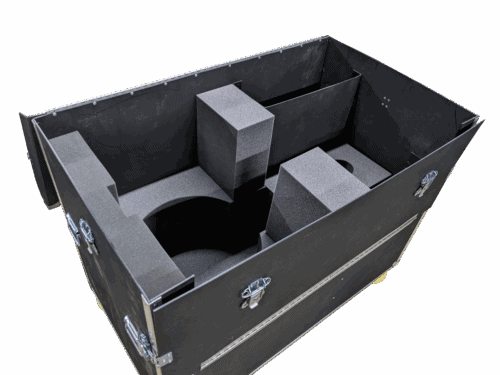

Wood Crates

All of our crates are stamped and certified for international export. Whether you need a single small crate delivered to you or dozens of oversized crates built onsite at your facility, we can handle the job. Our crates are fully customizable and can include foam, shelves, shock absorbers, ramps, latches, and more. We have experience building both commercial and military crates for equipment weighing 70,000+ lbs. Learn more here.

ATA / Road Cases

ATA / Road cases are best for highly sensitive objects that are light enough for one or two people to lift and move around. Our ATA cases can be either wood or plastic siding and all have durable metal edging. All ATA cases come with custom foam interiors and can have any number of wheels, handles, partitions, straps, latches, and more. Our cases are split or pop riveted together to ensure maximum strength and durability. Learn more here

PE & Wood Containers

If you need something lighter or cheaper than an ATA case, our PE and wood containers are the solution. PE containers are made with a strong, but lightweight, plastic siding and no metal edges. This provides a lighter and cheaper option to an ATA case, while still very durable. Our wood containers are made with wood sides and metal edges and are our most cost effective case option, but are heavier than the PE version. Learn more here.

Trunk Cases

Trunk cases are perfect for equipment regularly transported by box truck. Our trunk cases come in three sizes: Small - 22.5” x 30” x 30”, Medium - 22.5” x 45” x 30”, & Large 30” x 45” x 30”. These exterior dimensions allow them all to fit neatly in a box truck for maximum capacity. All trunk cases include handles, latches, four swivel castors, and castor cups on top to allow for secure stacking. As needed, labels, dividers, and foam can be added as well. Learn more here.

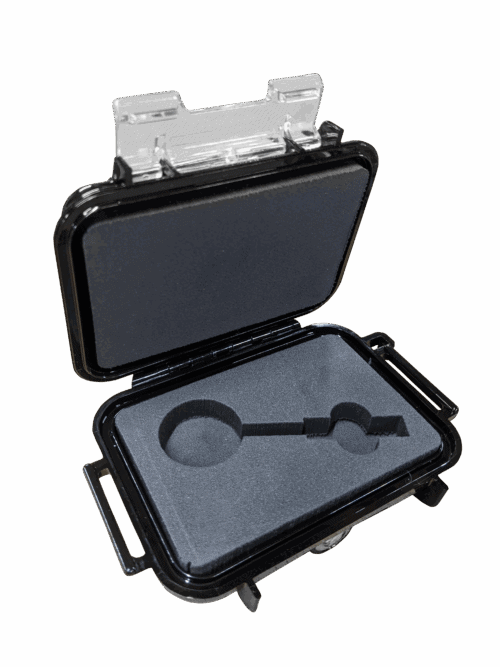

Injection Molded Cases

We are a certified distributor for Pelican, SKB, and Nanuk cases, meaning we offer better pricing than you’ll find anywhere else. All of our injection molded cases are watertight, comply with military specs, and are built to withstand the harshest environments. Custom waterjet or CNC cut foam inserts are available for all cases for maximum protection. Whether you need a case to hold one object or many, we can design a case for you. Learn more here.

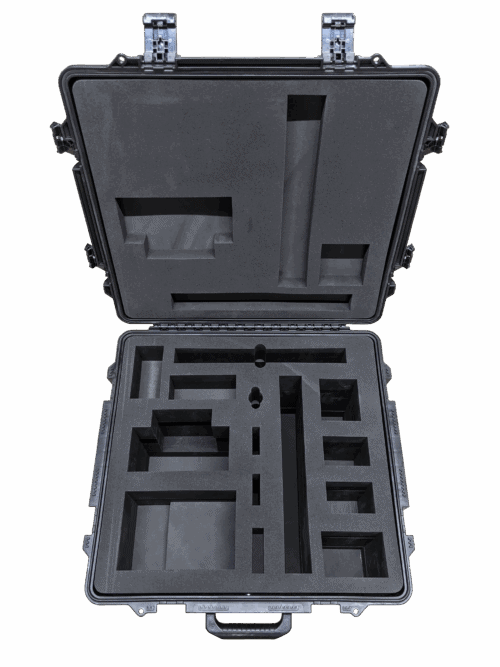

Waterjet & CNC Cut Foam

We offer a wide range of foam types, densities, and colors to best fit your needs. We offer foams types such as PE, PU, Crosslink, and Zote foam. All of these are available in a variety of densities depending on the weight and sensitivity of your equipment. We also offer colors other than the standard black/charcoal and have options such as anti-static. All these foam varieties can be waterjet or CNC cut to perfectly fit your product. Learn more here.

Contact Us

Whether you need one wood crate or hundreds of ATA cases, we’d love the chance to earn your business. All of our designs and quotes are done for free without any purchase required. We are able to work off dimensions/CAD files that you provide to us or we can visit your facility to take measurements of the equipment.

(865) 481-3801

sales@volcase.com

328 Warehouse Rd. Oak Ridge, TN 37830