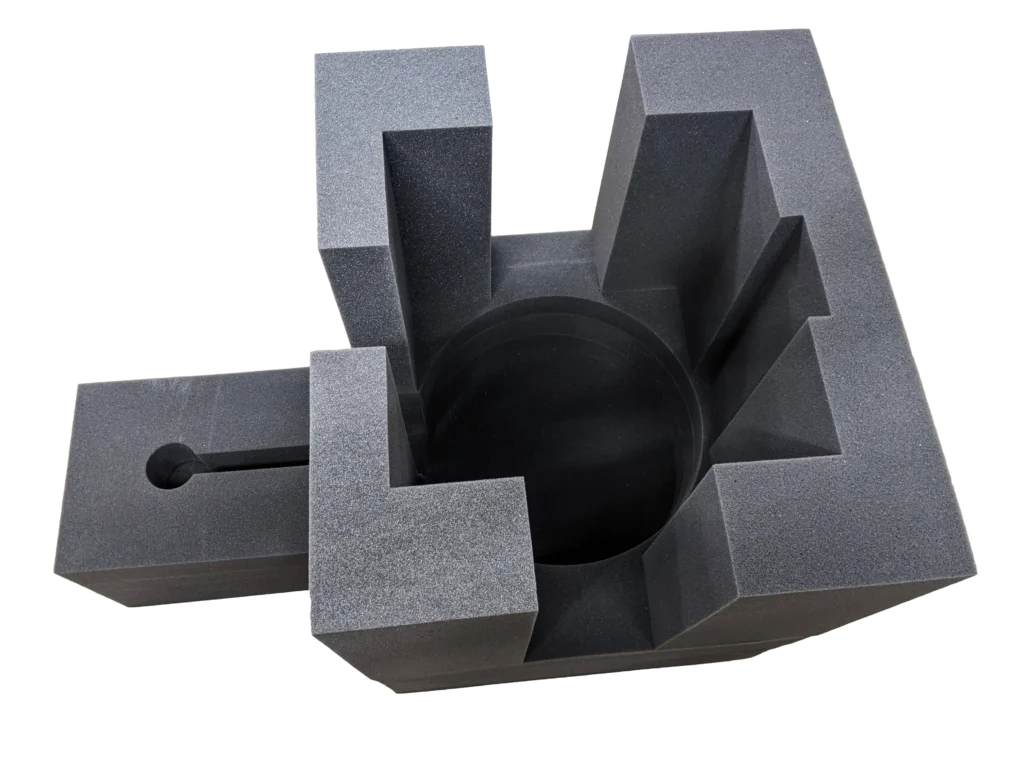

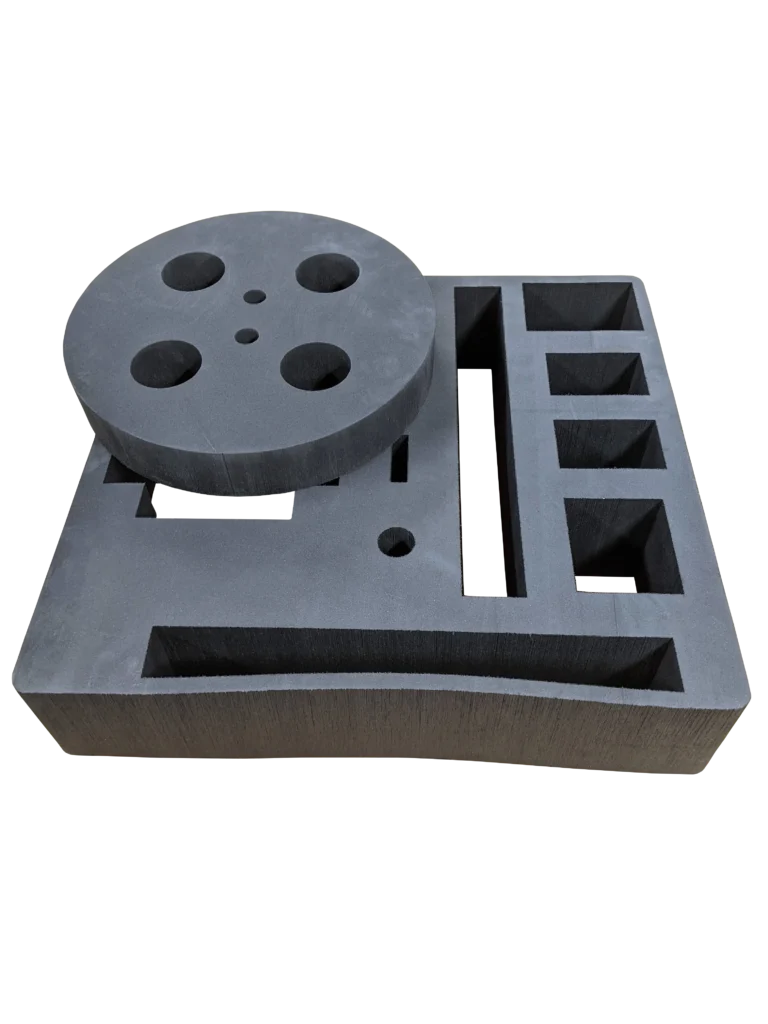

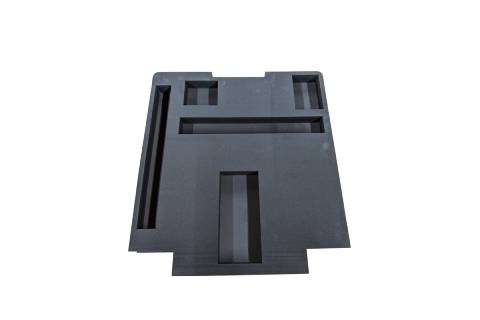

Custom Foam Inserts

Custom foam inserts and custom foam cutouts are frequent additions to our crates, cases, and containers. Installed on the interior, foam provides additional vibration and impact protection and a form-fitting bed for heavy, delicate, and expensive equipment to rest in.

We regularly manufacture custom boxes with foam inserts, wood crates lined with foam, ATA flight cases with foam inserts, and custom foam for Pelican cases, Nanuk cases, and SKB cases. No matter the crate or case you need, foam can easily be included in the design.

We offer a wide range of custom foam inserts of varying types, densities, and colors to best fit your needs, whether you need material with a high load-bearing capacity, moisture resistance, or anti-static properties. Our most common foam types are polyurethane (PU) and polyethylene (PE) as they are resilient, safe, and cost-effective. However, other types of foam, such as crosslink, Zotefoam, EVA, and others, can be used if needed.

PU Foam (Open-Cell)

PU foam is considered “open-cell” foam. It is typically lighter, less dense, and less rigid than PE foam, making it more suitable for more delicate equipment that needs extra padding and cushioning. It has high shock absorption and thus provides ideal protection against vibrations, drops, and other impacts that occur while in transit. It is often used to protect delicate, sensitive, and lighter equipment.

PE Foam (Closed-Cell)

PE foam is considered “closed-cell” foam. It is denser and more rigid, and its high compression strength allows it to withstand greater loads and pressure without collapsing or losing its shape. This makes it a good choice for cushioning heavy or bulky items that need to be transported over long distances or subjected to rough handling. It is also often used when insulation and airtightness and moisture resistance are important.

We have been installing custom foam inserts and cutouts for clients all across the country for over 30 years, so whether you need a simple foam shape installed in a single case or dozens of complex, custom-fit foam inserts installed in a large crate, we have the expertise to tackle all of your packaging and shipping challenges.

BENEFITS OF CUSTOM FOAM

Custom foam inserts augment the protection existing crates or cases provide your equipment and safeguard against wear and tear. Foam excels in being:

Precision-Fit

Cut by waterjet or CNC, our foam fits perfectly around your equipment ensuring maximum protection and ease of use.

Request A QuotePrecision-Fit

Cut by waterjet or CNC, our foam fits perfectly around your equipment ensuring maximum protection and ease of use.

Request A QuoteDurable

Designed to withstand continual use and regular loading / unloading without losing its protection, our foam inserts absorb shocks, vibrations, and impacts so your equipment doesn’t have to.

Request A QuoteLightweight

Light, easily compressible, and flexible, our foam provides ideal protection on a small footprint, minimizing necessary weight and space needs.

Request A QuoteVersatile

Whether you need high load-bearing capacity, moisture resistance, or anti-static properties, we have a wide array of foam types to meet your needs.

Request A QuoteCustomizable

Our foam can be cut to meet any shape and comes in a wide variety of types, densities, strength ratings, and colors to meet your needs.

Request A Quote

WATERJET CNC CUT FOAM FEATURES

OUR CUSTOM FOAM MANUFACTURING PROCESS

Our four-step production approach combines our expertise in design and

manufacturing with our commitment to exceeding your expectations. Our wood

crates protect your valuable equipment and other investments, saving on

replacement costs due to damage over the long term. Here’s an overview of our

manufacturing process that continues to provide customer satisfaction.

- 1. Consultation

-

Equipment measurements via sample products, drawings, 3D models, or an

in-person visit - Equipment details, such as the level of sensitivity

-

Crate use details, including how and where crates will be used, loading

and unloading requirements, etc. - Additional design or functionality requests

- 2. Crate Design

- 3. Prototyping

- 4. Approval and Production

First, we gather critical information from you, such as:

Based on the information from our consultation, we provide a complimentary

design of your wood crate, along with any ramps, latches, or custom foam

inserts / cutouts. We also provide you with an up-front quote for the crate to

avoid any surprises and confirm it’s within your budget considerations.

If desired, after the design and production quote are approved we can create a

prototype for you, usually completed within 2-3 weeks. Once yours is finished,

we review it with you and make any desired modifications.

After prototype approval, we finalize your custom design and move it into

production. Turnaround time is approximately 2 weeks, but our just-in-time

delivery service means your crates don’t have to arrive until you’re ready for

them. Completed designs are stored within our secure system, ready to move

right back into production in the future if you’d like to re-order or modify

the design.

INDUSTRY EXAMPLES

For more than three decades, we’ve built custom foam inserts and cutouts for a variety of industries, protecting valuable and sensitive equipment of all sizes in the most rugged and demanding environments, including:

Advanced Manufacturing

Tooling, gauges, small components, vision systems, spare parts, maintenance kits.

Request A QuoteAdvanced Manufacturing

Tooling, gauges, small components, vision systems, spare parts, maintenance kits.

Request A QuoteAerospace

Engine components, transmitters/receivers, gauges, test equipment, mechanic tools, detection systems.

Request A QuoteElectronics

Lasers, motherboards, power generation devices/components, tools and gauges, research equipment.

Request A QuoteGovernment and Military

Firearms, maintenance kits, field devices, small tools and gauges, communication systems.

Request A QuoteMedical

Imaging devices, miscellaneous cables and tubing, medical equipment, highly specialized medicines.

Request A QuoteNuclear

Lead components, radiation detection systems, radioactive storage containers.

Request A QuoteResearch

Robotics, computer systems, special tooling, server racks, lab supplies, centrifuges, sensitive instruments.

Request A QuoteSensing

Computer vision systems, infrared vision, LIDAR/RADAR, atmospheric sensing, spectrophotometers.

Request A Quote

CUSTOM FOAM BY VOLUNTEER CASE & CONTAINER

At Volunteer Case & Container, we are committed to delivering the superior quality your equipment deserves at the competitive prices you need. With an experienced design team, decades of practice, industry-leading two-week turnaround times, and no fees for designing your custom foam for crates, cases, containers, and more, we aim to be seen as true partners with you – working collaboratively to identify the best solution for your protective packaging needs.

Contact us or request a quote today to discuss your specific needs. You can also call us at (865) 481-3801 to learn more about our custom containers and other products.