Superior Protective Cases for Critical Missions: Built to Withstand

Superior Protective Cases for Critical Missions

In critical operations where equipment failure is not an option, protective cases serve as the first line of defense against environmental hazards, impact damage, and other threats. Whether for military deployments, industrial applications, or sensitive electronics transport, the right protective case can mean the difference between mission success and costly failure. This article explores the standards, features, and considerations that define truly superior protective cases for high-stakes scenarios.

Understanding Military-Grade Protection Standards

Military-grade protection has become a benchmark for premium protective cases, but what does this designation actually mean? The term refers to the United States Military Standard, commonly abbreviated as “MIL-STD” or “MIL-SPEC,” which represents standardization objectives established by the United States Department of Defense.

The MIL-STD-810G Specification

In the protective case industry, military-grade typically refers to MIL-STD-810H, a standard issued in 2019. This comprehensive standard includes a series of 29 testing methods covering various environmental conditions including pressure, temperature, humidity, vibration, shock, and even gunfire shock. When a protective case claims to be military-grade, it indicates that the product has undergone rigorous testing aligned with these standards. However, it’s worth understanding that not all 29 methods are mandatory for every product. Instead, appropriate methods are selected and tailored to generate the most relevant test data for a particular use case.

For instance, most cases are certified for MIL-SPEC-810 high and low temperature tests, but not the gunfire shock or pyroshock tests..

Multi-Layer Defense Systems in Premium Cases

Superior protective cases employ sophisticated multi-layer defense systems to safeguard contents against various threats. These systems combine different materials and design elements to create comprehensive protection.

Exterior Protection Elements

The outer shell of protective cases typically features a hard, durable layer that serves dual purposes: preventing water / dust from penetrating the case and spreading shock from any impacts. For cases designed for extreme environments, the exterior materials must also resist:

-

UV radiation damage

-

Chemical exposure

-

Abrasion and wear

-

Temperature fluctuations

-

Moisture infiltration

Interior Protection Systems

While exterior protection is crucial, the interior design of a protective case plays an equally important role in equipment safety. Premium cases feature inner foam that provide additional protection layers. These inner components often include:

-

Precision cut inserts to match exact equipment dimensions

-

Anti-static materials for electronic equipment

-

Moisture-absorbing elements

-

Vibration dampening systems

-

Pressure equalization valves

The combination of these exterior and interior elements creates a comprehensive protection system that addresses multiple threat vectors simultaneously. This multi-layered approach is what distinguishes truly superior protective cases from basic transportation containers.

Waterproof and Environmental Sealing Technologies

For missions in unpredictable environments, waterproofing and environmental sealing capabilities are non-negotiable features in protective cases. High quality cases, like Pelican or SKB, employ sophisticated sealing technologies to keep contents dry and clean regardless of external conditions.

|

IP Rating |

Protection Level |

What It Means |

|

IPX6 |

Dust-tight |

Complete protection against dust ingress |

|

IPX7 |

Water immersion |

Protected against water immersion up to 1 meter for 30 minutes |

|

IP68 |

Dust and water |

Dust-tight and protected against long-term immersion beyond 1 meter |

High-quality protective cases often feature IPX7 rated watertight seals and IPX6 dustproof protection. These ratings ensure that sensitive equipment remains protected even in challenging environments.

Advanced Sealing Mechanisms

Beyond basic rubber gaskets, premium protective cases incorporate advanced sealing technologies:

-

Pressure equalization valves that prevent vacuum lock while maintaining waterproof integrity

-

Tongue-and-groove designs with precision-engineered tolerances

-

Specialized polymer seals that remain flexible in extreme temperatures

These sealing mechanisms undergo rigorous testing, including submersion tests where cases are submerged in water one meter deep for one hour.

Customization Options for Mission-Specific Requirements

Every mission has unique requirements, and superior protective cases offer customization options to address specific needs. From custom foam inserts to specialized compartments, these customization features ensure equipment fits perfectly and remains secure during transport.

Custom foam inserts represent one of the most important customization options for protective cases. These inserts are:

-

Precisely cut to match equipment dimensions

-

Available in various densities for different weight and fragility requirements

-

Designed with finger pulls or lift points for easy equipment removal

-

Often layered to provide different protection zones

-

Available in anti-static versions for electronic components

Specialized Compartments and Features

Beyond foam customization, premium protective cases offer additional specialized features:

-

Integrated cable management systems

-

Document storage compartments

-

Humidity control systems

-

Trays to make objects easier to access in multi-layer foam sets

-

Straps, elastic, or buckle systems to secure equipment

These customization options allow organizations to create purpose-built protection solutions that address their specific operational requirements rather than settling for one-size-fits-all approaches.

Durability Testing and Quality Assurance

The difference between standard cases and truly superior protective solutions often comes down to rigorous testing and quality assurance processes. Premium manufacturers subject their cases to extreme conditions to ensure they’ll perform when it matters most.

Comprehensive Testing Protocols

Superior protective cases undergo extensive testing regimens that go beyond basic drop tests:

-

Repetitive Impact Testing: Cases must withstand multiple impacts that simulate real-world transportation scenarios.

-

Airline Travel Simulation: Quality cases are certified for a minimum of 100 airline trips, ensuring they can handle the rigors of frequent air transport.

-

Extreme Temperature Cycling: Cases are subjected to rapid temperature changes to test for material integrity and seal performance.

-

Long-Term Submersion: Water resistance is tested through extended submersion periods, not just brief exposure.

-

Vibration Resistance: Cases undergo vibration testing that simulates various transportation methods.

These comprehensive testing protocols ensure that protective cases will perform consistently in real-world conditions, not just in controlled laboratory environments. We typically partner with Ten-E Packaging Services for testing our products in accordance with these protocols.

Warranty and Guarantee Considerations

The confidence manufacturers have in their products is often reflected in their warranty offerings. Premium protective case manufacturers typically provide extensive warranty coverage:

-

Lifetime guarantees covering manufacturing defects

-

Repair or replacement policies for damaged cases

-

Performance guarantees for specific environmental conditions

-

Certification documentation for military and industrial standards

For example, some premium case manufacturers offer lifetime guarantees, promising that if there’s a problem with the case, it will either be repaired and returned or replaced with a new one.

Selecting the Right Protective Case for Critical Missions

Choosing the appropriate protective case for mission-critical equipment requires careful consideration of several factors. The right case balances protection requirements with practical considerations like weight, size, and accessibility.

Assessment Factors for Case Selection

When evaluating protective cases for sensitive equipment, consider these key factors:

-

Equipment Value and Sensitivity: More valuable or sensitive equipment justifies higher investment in protection. On average, we see customers spend about 2% of the item’s value on packaging.

-

Environmental Exposure: Consider the specific environmental threats the case must withstand.

-

Transportation Methods: Different transport modes (air, sea, land) present different challenges. Travel by sea will require greater moisture protection.

-

Frequency of Access: How often equipment needs to be accessed impacts case design requirements.

-

Number of Uses: Single use packaging will have a completely different design than multi-use packaging.

Weight Constraints: Total weight limitations may influence material and design choices. -

Regulatory Compliance: Some industries require specific certifications or standards compliance, like shipping wooden crates overseas.

Industry-Specific Considerations

Different sectors have unique requirements for their protective cases:

-

Military Applications: Require cases that meet specific MIL-STD requirements and often need to withstand extreme conditions.

-

Medical Equipment: Demands cases with exceptional cleanliness standards and often specialized compartments and foam.

-

Broadcasting and Media: Requires cases that provide quick access while still offering robust protection.

-

Industrial Equipment: Often needs cases that can handle heavy items while providing protection against dust and moisture.

-

Scientific Instruments: Requires precision foam cutting and often vibration isolation.

By carefully evaluating these factors and industry-specific requirements, organizations can select protective cases that provide optimal protection for their particular mission requirements.

Conclusion

Superior protective cases for critical missions go far beyond basic transportation containers. They represent sophisticated protection systems engineered to shield valuable equipment from multiple threat vectors simultaneously. From military-grade testing standards to advanced multi-layer defense systems, these cases incorporate numerous features that ensure mission success even in challenging environments.

When selecting protective cases for sensitive equipment, organizations should carefully evaluate their specific requirements and choose solutions that provide appropriate protection levels without compromising operational efficiency. By understanding the standards, features, and customization options available, decision-makers can ensure their critical equipment remains safe and functional regardless of external conditions.

For organizations that can’t afford equipment failure, investing in truly superior protective cases isn’t an expense—it’s insurance against mission failure and a commitment to operational excellence.

ABOUT VOL CASE

Volunteer Case & Container is the oldest custom crate and case manufacturer in the East TN area. Founded over 30 years ago, all of our protective packaging solutions are still designed and assembled at our facility in Oak Ridge, TN. We specialize in custom wood crates, ATA cases, wood or plastic containers, injection molded cases, and waterjet or CNC cut foam inserts. Our customers span a variety of industries including nuclear, government, aerospace, military, medical, R&D, and more. Our team has experience designing and building everything from huge wood crating for 70,000+ lbs machinery to small injection molded cases for key-sized objects. Whatever your needs, our team works on quick turnaround times to provide you with high quality protective packaging. Contact us today for a free quote.

Our Products

No matter the size or sensitivity of your product, Vol Case has a protective packaging shipping solution for you.

Wood Crates

All of our crates are stamped and certified for international export. Whether you need a single small crate delivered to you or dozens of oversized crates built onsite at your facility, we can handle the job. Our crates are fully customizable and can include foam, shelves, shock absorbers, ramps, latches, and more. We have experience building both commercial and military crates for equipment weighing 70,000+ lbs. Learn more here.

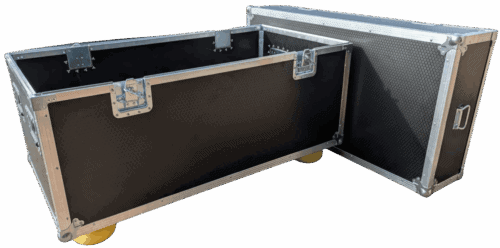

ATA / Road Cases

ATA / Road cases are best for highly sensitive objects that are light enough for one or two people to lift and move around. Our ATA cases can be either wood or plastic siding and all have durable metal edging. All ATA cases come with custom foam interiors and can have any number of wheels, handles, partitions, straps, latches, and more. Our cases are split or pop riveted together to ensure maximum strength and durability. Learn more here

PE & Wood Containers

If you need something lighter or cheaper than an ATA case, our PE and wood containers are the solution. PE containers are made with a strong, but lightweight, plastic siding and no metal edges. This provides a lighter and cheaper option to an ATA case, while still very durable. Our wood containers are made with wood sides and metal edges and are our most cost effective case option, but are heavier than the PE version. Learn more here.

Trunk Cases

Trunk cases are perfect for equipment regularly transported by box truck. Our trunk cases come in three sizes: Small - 22.5” x 30” x 30”, Medium - 22.5” x 45” x 30”, & Large 30” x 45” x 30”. These exterior dimensions allow them all to fit neatly in a box truck for maximum capacity. All trunk cases include handles, latches, four swivel castors, and castor cups on top to allow for secure stacking. As needed, labels, dividers, and foam can be added as well. Learn more here.

Injection Molded Cases

We are a certified distributor for Pelican, SKB, and Nanuk cases, meaning we offer better pricing than you’ll find anywhere else. All of our injection molded cases are watertight, comply with military specs, and are built to withstand the harshest environments. Custom waterjet or CNC cut foam inserts are available for all cases for maximum protection. Whether you need a case to hold one object or many, we can design a case for you. Learn more here.

Waterjet & CNC Cut Foam

We offer a wide range of foam types, densities, and colors to best fit your needs. We offer foams types such as PE, PU, Crosslink, and Zote foam. All of these are available in a variety of densities depending on the weight and sensitivity of your equipment. We also offer colors other than the standard black/charcoal and have options such as anti-static. All these foam varieties can be waterjet or CNC cut to perfectly fit your product. Learn more here.

Contact Us

Whether you need one wood crate or hundreds of ATA cases, we’d love the chance to earn your business. All of our designs and quotes are done for free without any purchase required. We are able to work off dimensions/CAD files that you provide to us or we can visit your facility to take measurements of the equipment.

(865) 481-3801

sales@volcase.com

328 Warehouse Rd. Oak Ridge, TN 37830