Polyethylene (PE) and Wood Containers

When weight and cost are the biggest focus areas, our polyethylene (PE) or wood containers may be the best solution. If transportation costs are your biggest concern, our PE cases are the lightest case available while remaining durable and protective. Wood containers, on the other hand, are perfect for tight budget projects. Both container styles have been trusted around the world for several decades and proven to protect sensitive equipment.

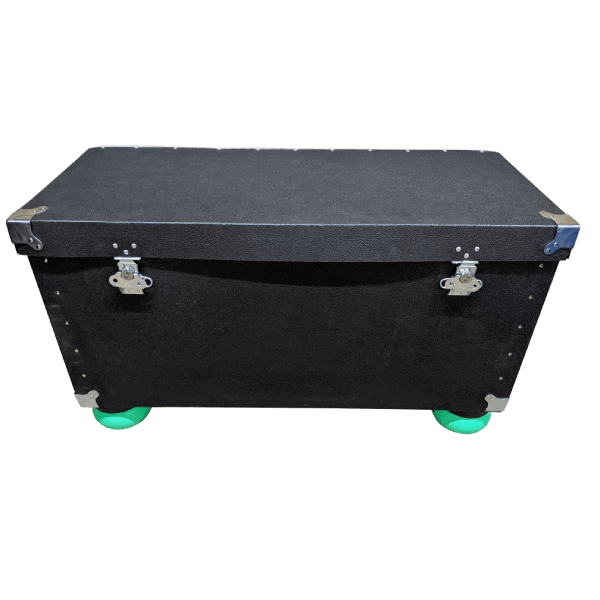

Our PE containers are made with a strong, but lightweight, plastic siding and no metal edges. Using less metal allows for a significantly lighter case while the plastic siding still provides a strong and flexible outer shell. This allows the case to easily bounce back from impacts without long lasting damage.

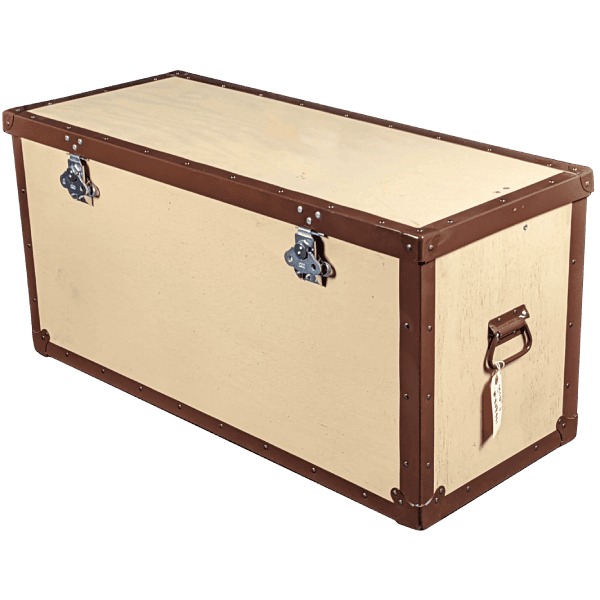

If budget constraints are the primary concern, our wood containers provide the perfect balance of a rigid plywood outer shell with strong metal edging without breaking the bank. These containers can also be painted to match your brand if desired.

All of our containers are custom-built to meet your needs. In addition to size, we also add interior customizable foam inserts and custom foam cutouts to ensure a tight product fit and provide additional protection. Latches, locks, hinges, wheels, castors, and other add-ons are also frequently used based on product needs and use.

We have been sending PE and wood containers all over the world for over 30 years, so whether you need a single small PE container or dozens of large wood containers, we have the expertise to tackle all of your packaging and shipping challenges.

BENEFITS OF PE AND WOOD CONTAINERS

PE and wood containers are ideal for transporting equipment lighter enough to be picked up by 1-2 people but does not fit into a standard injection molded case size. PE and wood containers excel in being:

Lightweight

Lighter than similarly sized crates or cases, PE and wood containers are easier to lift, move, and ship.

Request A QuoteLightweight

Lighter than similarly sized crates or cases, PE and wood containers are easier to lift, move, and ship.

Request A QuoteDurable

Despite their light weight, our containers are designed to withstand repeated loading / unloading, vibrations while in transit, and general wear and tear.

Request A QuoteStackable

Many of our PE and wood containers are safely and easily stackable, reducing required storage footprint.

Request A QuoteSecure

Latches, locks, and reinforced hinges ensure our containers remain safe and secure.

Request A QuoteCustomizable

We can outfit any container with a variety of features, including customizable foam inserts, latches, handles, skid mates, colors, and more.

Request A Quote

PE AND WOOD CONTAINERS FEATURES

OUR PE AND WOOD CONTAINER MANUFACTURING PROCESS

Our four-step production approach combines our expertise in design and

manufacturing with our commitment to exceeding your expectations. Our wood

crates protect your valuable equipment and other investments, saving on

replacement costs due to damage over the long term. Here’s an overview of our

manufacturing process that continues to provide customer satisfaction.

-

- 1. Consultation

First, we gather critical information from you, such as:

-

-

- Equipment measurements via sample products, drawings, 3D models, or an

in-person visit - Equipment details, such as the level of sensitivity

- Crate use details, including how and where crates will be used, loading

and unloading requirements, etc. - Additional design or functionality requests

- Equipment measurements via sample products, drawings, 3D models, or an

-

-

- 2. Crate Design

Based on the information from our consultation, we provide a complimentary

design of your wood crate, along with any ramps, latches, or custom foam

inserts / cutouts. We also provide you with an up-front quote for the crate to

avoid any surprises and confirm it’s within your budget considerations.

-

- 3. Prototyping

If desired, after the design and production quote are approved we can create a

prototype for you, usually completed within 2-3 weeks. Once yours is finished,

we review it with you and make any desired modifications.

-

- 4. Approval and Production

After prototype approval, we finalize your custom design and move it into

production. Turnaround time is approximately 2 weeks, but our just-in-time

delivery service means your crates don’t have to arrive until you’re ready for

them. Completed designs are stored within our secure system, ready to move

right back into production in the future if you’d like to re-order or modify

the design.

INDUSTRY EXAMPLES

For more than three decades, we’ve built custom PE and wood containers for a variety of industries, protecting valuable and sensitive equipment of all sizes in the most rugged and demanding environments, including:

Advanced Manufacturing

Tooling, gauges, small components, vision systems, spare parts, maintenance kits.

Request A QuoteAdvanced Manufacturing

Tooling, gauges, small components, vision systems, spare parts, maintenance kits.

Request A QuoteAerospace

Engine components, transmitters/receivers, gauges, test equipment, mechanic tools, detection systems.

Request A QuoteElectronics

Lasers, motherboards, power generation devices/components, tools and gauges, research equipment

Request A QuoteGovernment and Military

Firearms, maintenance kits, field devices, small tools and gauges, communication systems.

Request A QuoteMedical

Imaging devices, miscellaneous cables and tubing, medical equipment, highly specialized medicines.

Request A QuoteNuclear

Lead components, radiation detection systems, radioactive storage containers.

Request A QuoteResearch

Robotics, computer systems, special tooling, server racks, lab supplies, centrifuges, sensitive instruments.

Request A QuoteSensing

Computer vision systems, infrared vision, LIDAR/RADAR, atmospheric sensing, spectrophotometers.

Request A Quote

PE AND WOOD CONTAINERS BY VOLUNTEER CASE & CONTAINER

At Volunteer Case & Container, we are committed to delivering the superior quality your equipment deserves at the competitive prices you need. With an experienced design team, decades of practice, industry-leading two-week turnaround times, and no fees for designing your custom container, we aim to be seen as true partners with you – working collaboratively to identify the best solution for your protective packaging needs.

Contact us or request a quote today to discuss your specific needs. You can also call us at (865) 481-3801 to learn more about our custom containers and other products.