The Difference Between Waterjet-Cut Foam and CNC-Cut Foam

When it comes to cutting custom foam inserts for various applications, there are two main methods that are commonly used: waterjet cutting and CNC cutting. Both methods have their own unique advantages and disadvantages, and the best option for your project will depend on your specific needs and requirements.

WHAT IS WATERJET CUTTING?

Waterjet cutting is a process that uses a high-pressure stream of water to cut through the foam. The water is mixed with an abrasive material, such as garnet or alumina, which allows the waterjet to cut through even the toughest materials with precision and accuracy. Waterjet cutting is ideal for cutting large volumes quickly, and it produces clean, smooth edges without causing any deformation to the foam.

WHAT IS CNC CUTTING?

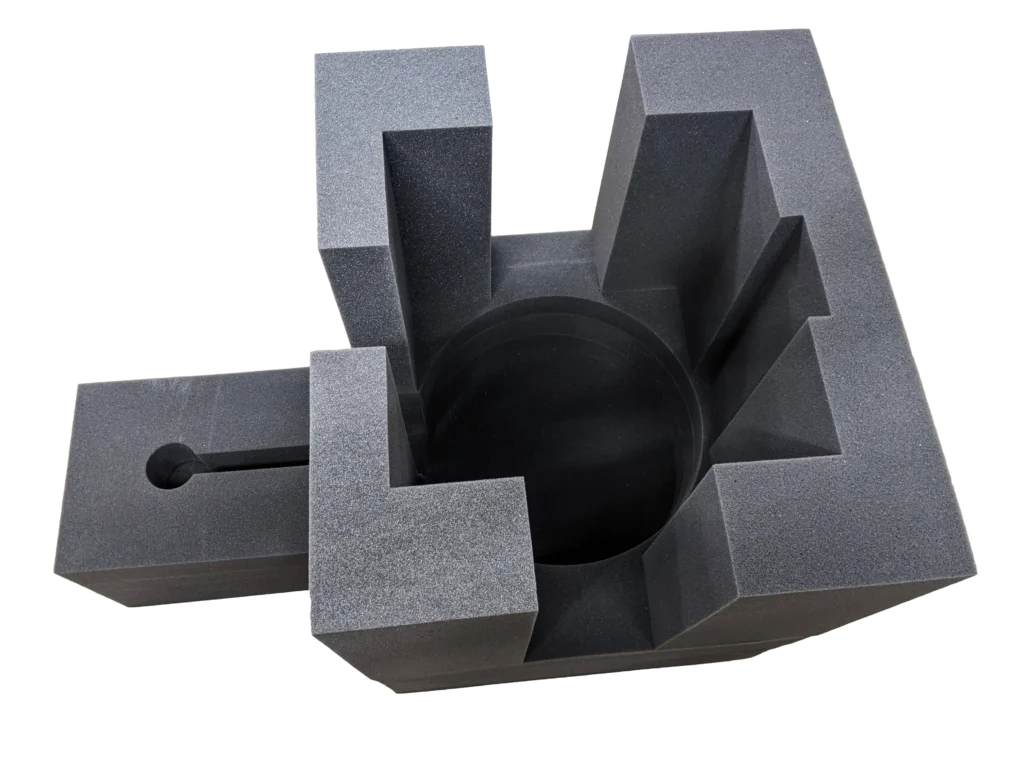

CNC cutting, on the other hand, uses a computer-controlled cutting tool to cut the foam. The cutting tool is typically a rotating bit and is programmed to follow a specific cutting path. CNC cutting is ideal for cutting foam pieces that have several different depths. A waterjet only has one depth option, which is all the way through the foam. Therefore, every unique depth in the foam needs to be a separate layer or plug. So if you require the foam to be made from only one piece of material, the CNC cut foam would be your best option.

WHAT’S THE DIFFERENCE?

One of the key differences between waterjet-cut foam and CNC-cut foam is the level of precision and accuracy that can be achieved. Waterjet cutting allows for incredibly fine tolerances and detailed designs, whereas CNC cutting is generally not as precise. This is because the CNC router bit tends to push the material slightly before cutting it. This creates slightly less precise cuts. In addition, CNC router cutting is only an option for closed-cell foams, therefore, polyurethane (PU) foam has to be waterjet- cut. This is because CNC tables tend to use vacuum tables to secure the material, but this does not work on open-celled foam like PU.

Another major difference between waterjet-cut foam and CNC-cut foam is the cost. Waterjet cutting is typically more expensive than CNC cutting for small quantities, as it requires specialized equipment and highly trained operators. CNC cutting, on the other hand, is more expensive for large quantities as it is not as quick as a waterjet.

IN CONCLUSION

In conclusion, waterjet-cut foam and CNC-cut foam are both effective methods for cutting foam, but they have different strengths and weaknesses. Waterjet cutting is ideal for cutting high-volume production runs, while the CNC is best for small batches or for foam pieces that need increased strength and therefore should be cut from one piece of material. It is important to know that no matter how your custom foam inserts are cut, they can be installed in custom boxes, Pelican cases, ATA cases, or any other product we manufacture.

ABOUT VOL CASE

Volunteer Case & Container is the oldest custom crate and case manufacturer in the East TN area. Founded over 30 years ago, all of our protective packaging solutions are still designed and assembled at our facility in Oak Ridge, TN. We specialize in custom wood crates, ATA cases, wood or plastic containers, injection molded cases, and waterjet or CNC cut foam inserts. Our customers span a variety of industries including nuclear, government, aerospace, military, medical, R&D, and more. Our team has experience designing and building everything from huge wood crating for 70,000+ lbs machinery to small injection molded cases for key-sized objects. Whatever your needs, our team works on quick turnaround times to provide you with high quality protective packaging. Contact us today for a free quote.

OUR PRODUCTS

No matter the size or sensitivity of your product, Vol Case has a protective packaging shipping solution for you.

Wood Crates

All of our crates are stamped and certified for international export. Whether you need a single small crate delivered to you or dozens of oversized crates built onsite at your facility, we can handle the job. Our crates are fully customizable and can include foam, shelves, shock absorbers, ramps, latches, and more. We have experience building both commercial and military crates for equipment weighing 70,000+ lbs. Learn more here.

ATA / Road Cases

ATA / Road cases are best for highly sensitive objects that are light enough for one or two people to lift and move around. Our ATA cases can be either wood or plastic siding and all have durable metal edging. All ATA cases come with custom foam interiors and can have any number of wheels, handles, partitions, straps, latches, and more. Our cases are split or pop riveted together to ensure maximum strength and durability. Learn more here

PE & Wood Containers

If you need something lighter or cheaper than an ATA case, our PE and wood containers are the solution. PE containers are made with a strong, but lightweight, plastic siding and no metal edges. This provides a lighter and cheaper option to an ATA case, while still very durable. Our wood containers are made with wood sides and metal edges and are our most cost effective case option, but are heavier than the PE version. Learn more here.

Trunk Cases

Trunk cases are perfect for equipment regularly transported by box truck. Our trunk cases come in three sizes: Small - 22.5” x 30” x 30”, Medium - 22.5” x 45” x 30”, & Large 30” x 45” x 30”. These exterior dimensions allow them all to fit neatly in a box truck for maximum capacity. All trunk cases include handles, latches, four swivel castors, and castor cups on top to allow for secure stacking. As needed, labels, dividers, and foam can be added as well. Learn more here.

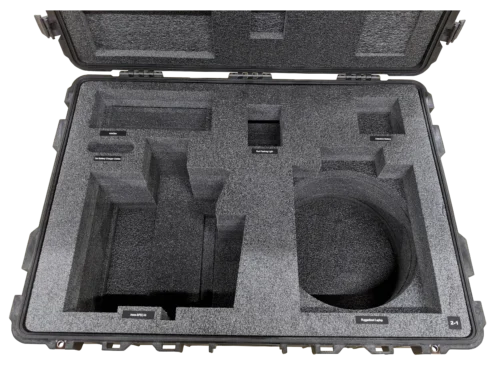

Injection Molded Cases

We are a certified distributor for Pelican, SKB, and Nanuk cases, meaning we offer better pricing than you’ll find anywhere else. All of our injection molded cases are watertight, comply with military specs, and are built to withstand the harshest environments. Custom waterjet or CNC cut foam inserts are available for all cases for maximum protection. Whether you need a case to hold one object or many, we can design a case for you. Learn more here.

Waterjet & CNC Cut Foam

We offer a wide range of foam types, densities, and colors to best fit your needs. We offer foams types such as PE, PU, Crosslink, and Zote foam. All of these are available in a variety of densities depending on the weight and sensitivity of your equipment. We also offer colors other than the standard black/charcoal and have options such as anti-static. All these foam varieties can be waterjet or CNC cut to perfectly fit your product. Learn more here.

CONTACT US

Whether you need one wood crate or hundreds of ATA cases, we’d love the chance to earn your business. All of our designs and quotes are done for free without any purchase required. We are able to work off dimensions/CAD files that you provide to us or we can visit your facility to take measurements of the equipment.

(865) 481-3801

sales@volcase.com

328 Warehouse Rd. Oak Ridge, TN 37830